With the continuous development of injection molding machine control, most of the old small and medium-sized injection molding machine electronic control systems use relay control, which has complex circuits, high failure rates, and troublesome maintenance, resulting in low production efficiency. Injection molding machine control uses programmable controllers (PLC) , has the characteristics of high reliability, easy programming, strong anti-interference ability, and convenient maintenance. The entire process of the PLC-based injection molding machine control system is mainly applied by the hydraulic system and PLC, making the control of the injection molding machine more convenient for the execution of the machine. Mechanisms (motors, valves, etc.) complete the entire process in a certain order. The safety isolation transformer plays a very important role in the entire injection molding machine control system.

Interference signals cause malfunction of the injection molding machine by interfering with the controller, resulting in large errors, low precision, difficulty in maintenance and other shortcomings. The power supply is one of the main ways for interference signals to enter the controller; using an isolation transformer can improve the resistance. High-frequency common-mode interference capability. The transformer is shielded and grounded, which can disconnect the interference channel from the input end to the output end, and has a good effect on suppressing external interference from the power line.

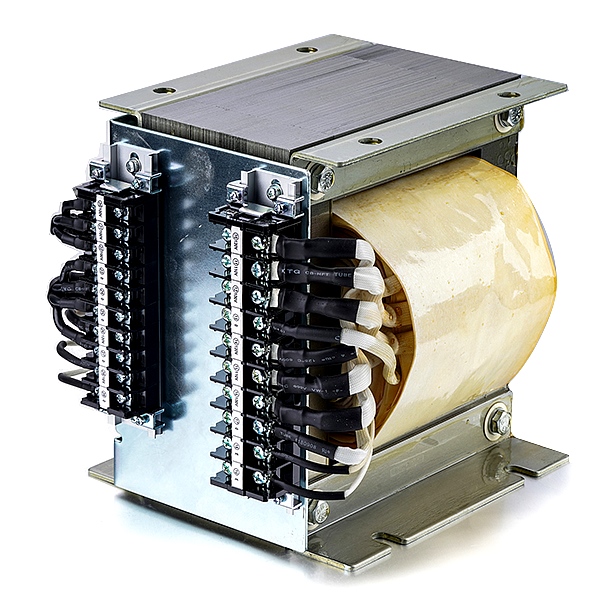

Transformer features:

1. The internal insulation method adopts F-class insulation and above, Do pont high temperature resistant Nomex insulation material, high heat resistance coefficient and strong safety

2. The iron core is made of high-quality silicon steel sheets less than or equal to 0.35mm, and the winding coil is made of enameled wire less than or equal to 180 degrees Celsius. The product has low loss, high efficiency and low voltage regulation rate.

3. Using H-class insulating paint vacuum impregnation, the product can work continuously and at full load in harsh environments such as high oil stains, high room temperature, and high dust.

The transformer of the industrial injection molding machine is a dual-proportional pressure and flow control, and the mechanical structure is optimized. It not only operates smoothly, but also is faster than normal. Its slide plate and bottom plate are made of ductile iron, and the connecting parts are isolated by steel strips. There are lubricating oil holes, which greatly reduce the wear and tear of the skateboard, reduce the deformation, and greatly increase the service life and accuracy of the skateboard. The thimble can be used according to different skateboards, and the stroke can be adjusted according to the operation. The mold force, ejector advance and retreat speed and demoulding times can also be pre-set according to operational needs. There is also a dual-mode slide plate, which uses two molds to slide left and right alternately, one mold is formed, and the other mold is embedded in the outside. This kind of operation is not only It has high safety performance and can increase productivity by 30%-50%.

The diversified oil circuit system design of industrial injection molding machine transformers (semi-closed, fully closed, servo or high-speed injection molding) can not only meet customer needs, but also expand program design and connect with automatic embedding and removal equipment to achieve one-click Fully automatic operation.

| Industrial injection molding machine transformer Specification model: EI218100 Rated power: 4KVA Rated frequency:50\/60Hz Rated input: AC 0-100V-110V-120V\/0-100V-110V-120V Rated output: AC 0-100V\/31A-120V\/7.5A, 18V\/1A Insulation level: CLASS H Altitude: less than or equal to 1000 Winding material: copper |