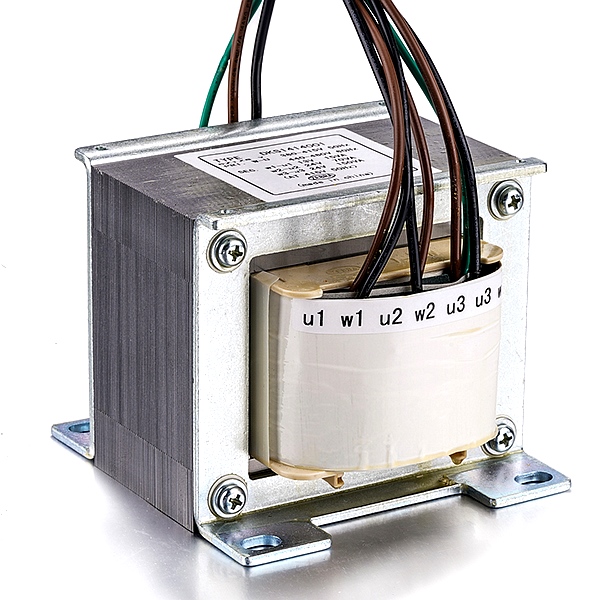

Industrial air conditioning transformers play an important role in industrial environments. They help maintain a constant voltage supply to ensure the normal operation of industrial air conditioners. In order to ensure the reliability and extend the life of the transformer, regular care and maintenance work is crucial. This article will introduce how to perform maintenance work to ensure its normal operation.

1. Maintain lubrication system

The lubrication system plays a key role inside the transformer, helping to reduce internal friction and reduce temperature rise. Key steps to maintain the lubrication system include:

Change the lubricating oil: Change the lubricating oil regularly according to the manufacturer's recommendations. Fresh lubricating oil can ensure the normal operation of the lubrication system.

Check the lubrication system: Check the pipes, oil pumps and filters of the lubrication system to make sure they are not clogged or leaking. Repair or replace damaged parts.

Maintain oil level: Keep lubricating oil at the appropriate oil level. Add or drain lubricating oil into the lubrication system to maintain the oil level within the normal range.

2. Regularly check insulation materials

Insulation materials are critical to protecting the transformer’s internal components from moisture and impurities. Inspection and maintenance of insulation materials include:

Check the insulating oil: Check the status of the insulating oil regularly to ensure it is clean and free of impurities. Replace the insulating oil if necessary and perform oil treatment as needed.

Maintain seals: Check the sealing parts of the industrial air conditioning transformer, including gaskets, sealing rings and sealant, to ensure there are no leaks. Repair or replace damaged sealing parts.

Monitor insulation resistance: Monitor the condition of insulation materials by regularly measuring insulation resistance. Low resistance may indicate that the insulation material is damaged and needs repair or replacement.

3. Regularly check circuits and connections

Proper operation of circuits and connections is critical to the performance of your transformer. Regular inspection and maintenance include:

Check cables and connections: Check cables and connections to make sure they are not loose or damaged. Repair or replace damaged cables and connections.

Tighten screws and nuts: Check screws and nuts regularly to make sure they are tight. Loose screws and nuts may cause poor connections and malfunctions.

Regular care and maintenance work is key to ensuring the normal operation of industrial air conditioning transformers. Therefore, it is important to follow the manufacturer's recommendations and perform regular routine inspections to ensure that the transformer continues to play its important role in the industrial environment.